Water flow rate is often a critical measurement for various power plant components and systems including cooling towers, pumps, and condensers. For over 40 years the Simplex-type Pitot Tube has been the industry standard for accurate water flow measurement, however the Simplex Tube is no longer commercially available.

In addition, the results of from Simplex Tubes have long been suspect in the most challenging flow situations. Under contract to the Cooling Technology Institute (CTI), CleanAir conducted a research study to identify alternative pitot designs (CTI Case Study). This work culminated in 2017 with the introduction of the Elliptical Pitot Tip.

Advantages of the Elliptical Pitot tube Tip include:

- Less sensitivity to Reynolds number

- Allows measurements closer to the pipe wall than other designs

- Better accuracy in disturbed flow situations

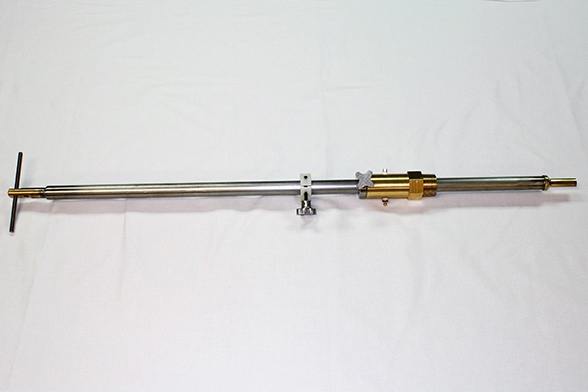

With the new design providing more accurate flow determinations especially when the flow profile is disturbed, CleanAir will begin using the new design for flow rate measurements in 2018. Unreinforced pitot tubes have a maximum working length of 68” and are generally used for pipes that are less than 42 inches in diameter. For larger pipe sizes or pipes with higher than normal velocities, CleanAir offers an elliptical pitot “stinger” design that can be inserted into a 1-1/2 inch reinforcing rod of up to 20 ft in length.

Each assembled pitot tube includes:

- 1-1/4” NPT packing gland with locking collar, dual O-rings, and grease fitting

- Quick disconnect fittings that prevent flow when not connected

- Locking shaft collar for ease of marking the far wall of the pipe (automatically adjusts for 1/8” distance between tip and impact port)

- Construction from highly corrosion resistant 316 stainless steel and brass

Each pitot stinger includes:

- Two 1/8” NPT to ¼” barb fittings from the impact and static pressure ports

- Low profile hose clamps

- Three O-rings

- Construction from highly corrosion resistant 316 stainless steel and brass

Each pitot will be dimensioned from the sensing tip to end where handles can be used for alignment and rotation as needed. Each pitot stinger will be dimensioned as the full length protruding from the end of the reinforcing rod. Packing glands will be included to accommodate pitot insertion in an active pipe.

Calibration services are available across a variety of flow settings and fluid velocities.

CleanAir will supply a procedure for how to measure flow and a flow calculation spreadsheet for pitot station calculation and flow calculation consistent with CTI methodology with each pitot tube or pitot stinger purchase.